product details

Multi - head filling machine (with chuck - type vibration filling) sealing, capping and inkjet printing production line

No:

Category:

The automatic granule electronic weighing and sealing production line is mainly used for weighing and filling, sealing, capping, labeling, and packing of bottled dried fruit electronic scales. It is mainly applicable to nuts, pistachios, raisins, medberries, tea, sesame, melon seeds, and peanuts!

inquiry

- Features

- Scope of application

- Technical parameter

- Drawing

-

- Commodity name: Multi - head filling machine (with chuck - type vibration filling) sealing, capping and inkjet printing production line

- Commodity ID: Multi - head filling machine

The automatic granule electronic weighing and sealing production line is mainly used for weighing and filling, sealing, capping, labeling, and packing of bottled dried fruit electronic scales. It is mainly applicable to nuts, pistachios, raisins, medberries, tea, sesame, melon seeds, and peanuts!

Scope of application:

The bottled nut weighing and filling production line is mainly used for weighing and filling, sealing, capping, labeling, and packing of bottled dried fruit electronic scales. It is mainly applicable to nuts, pistachios, raisins, medberries, tea, sesame, melon seeds, and peanuts!

Equipment composition:

The automatic packaging production line for plastic bottled food is composed of Z elevator, automatic weighing particle filling machine, top cap capping machine, automatic labeling machine, and bottle sorting machine. Among them, the particle filling machine adopts advanced modes such as PLC+servo motor+touch screen. The whole equipment has stable performance, high precision, and all stainless steel structure. The entire filling process uses an intelligent control system, which can complete the automatic positioning, filling and metering of bottles. It is composed of a filling head, a chain plate conveyor belt and a positioning device. It is an economical and practical automatic filling machine for powder and small particles. In addition, this set of equipment is equipped with a height adjusting handwheel with reasonable position, which is convenient for adjusting the head height. The supporting devices include: pneumatic valve device, leak proof centrifugal device, supporting tank device, horizontal open hopper, online weighing and metering device, and dust removal device

Bottled nut weighing and filling production line (Figure 2)

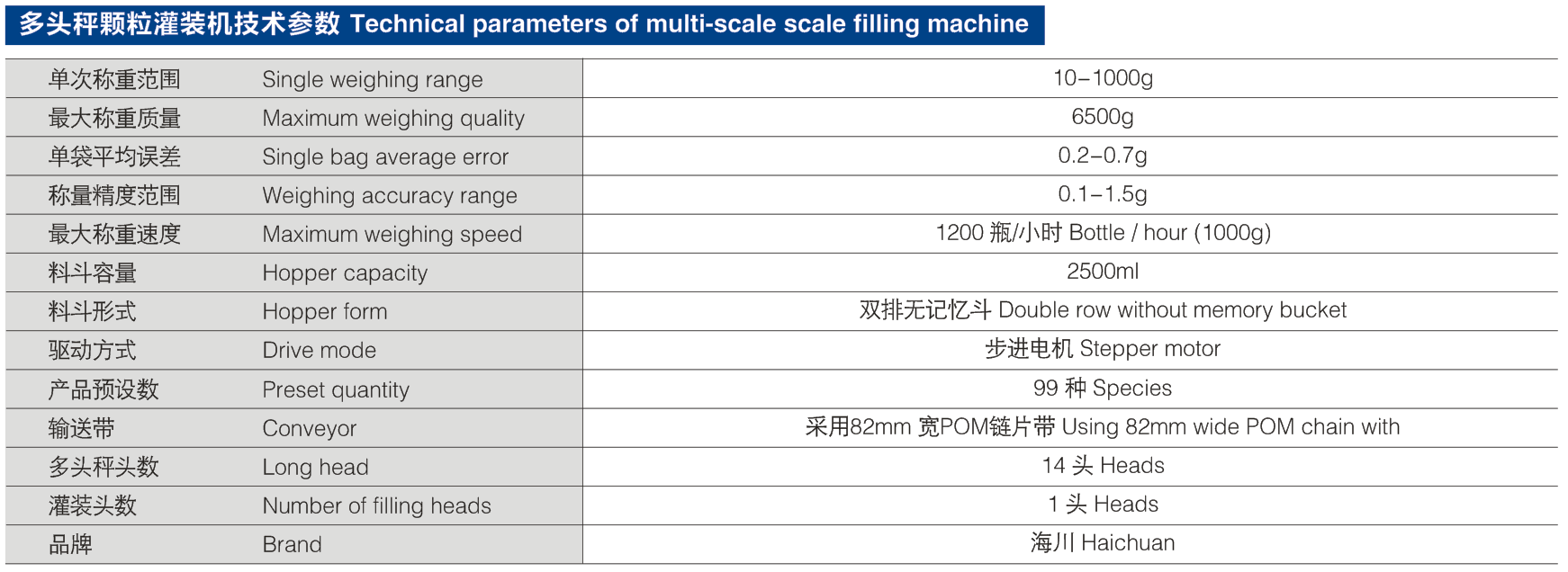

Technical parameters:

Filling speed: 15 - 60 times/minute&# 160;

Canning accuracy: ≥ 500g, ± 0.5%, 100-1000g, ≤± 2g

Package weight: 50 - 1000kg (adjustable)

Power supply: three-phase 380V 50-60HZ

Overall power: 2.7KW

Bin volume: 45L (larger 65L) 70L () loader

Total volume: 3000 × nine hundred and seventy × 2300mm

Metering method: electronic scale weighing method or screw metering

Operating Weight: 450

Key words:- Automatic particle electronic weighing can sealing production line

- Filling production line

- Electronic weighing filling machine

-

Scope of application:

The bottled nut weighing and filling production line is mainly used for weighing and filling, sealing, capping, labeling, and packing of bottled dried fruit electronic scales. It is mainly applicable to nuts, pistachios, raisins, medberries, tea, sesame, melon seeds, and peanuts!

-

ONLINE MESSAGE

Related products

020-81775841

020-81775841

Email

Email